SKU : BVE-V10

Categories : 12. Lab Equipment , Electrophoresis system , Servicebio ,

Brand : Servicebio

Share

High-Throughput Gel Casting Stand

Can prepare 10 gels at once with patented magnetic base design - leak-proof, durable and easy to operate for more efficient WB experiments.

Product Overview

Designed for preparing SDS-PAGE gels, it can produce up to 10 gels at once with thicknesses of 0.75mm, 1.0mm, or 1.5mm. The gel-casting stand features a magnetic base and easy-to-use clips, making gel preparation more convenient. When used with the gel casting stand (T-20), it enables batch preparation of 4%-20% gradient gels or uniform-concentration gels in one go, improving WB efficiency and results.

Product Parameters

Cat.No. | BVE-V10 |

Gel Size | 83×73mm |

Dimensions | 408×177×86mm |

Compatible Glass and Spacer | 1.0mm: 11-tooth/15-tooth |

Sealing Rubber Size | 115×18×5mm |

Maximum Pressure Capacity | 10 plates |

1. Preparation

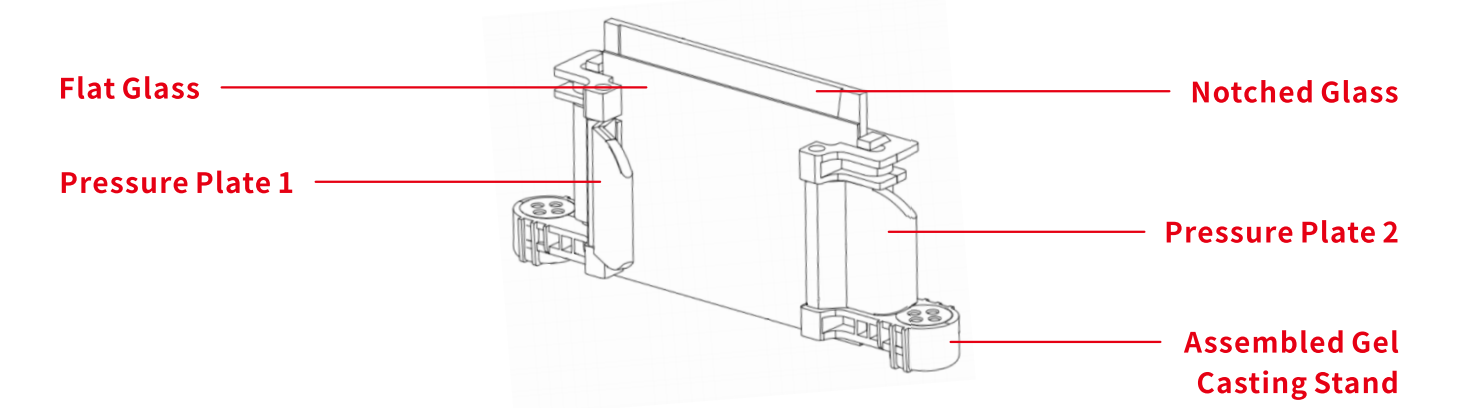

Place the gel casting clamp on a flat table surface, Fully open the pressure plates on the clamp (pressure plates 1),then insert the flat glass and the notched glass, Ensure the flat glass is positioned at the bottom opening of the notched glass, and secure both sides bytightening the pressure plates (pressure plates 2).

Note

Before starting, check whether the notched glass and flat glass are properly separated, whether the glass cover is

fully sealed, and whether the pressure plates at both ends ofthe glass are securelyfastened.

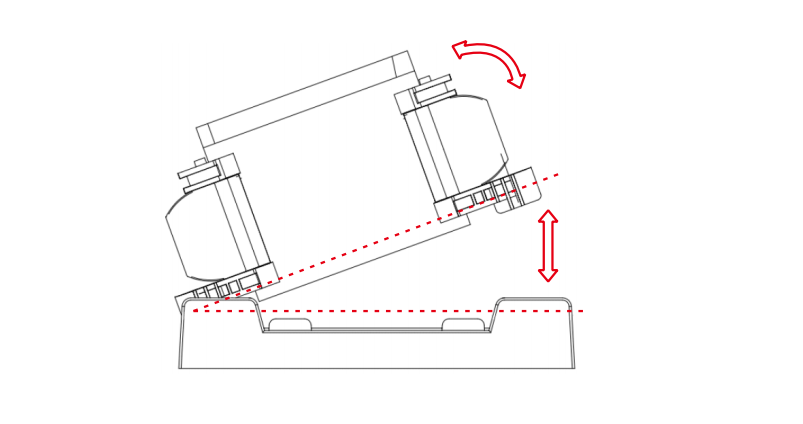

2. Gel Casting

First, attach one end of the gel casting clamp to the plastic base plate, then press the other end firmly onto the base plate until it snaps into place. Pour the gel solution between the two glass plates until it reaches approximately 1/3 to 1/4 of the height of the metal spacer (adjust as needed). After pouring, gently tap the glass plates to ensure even distribution ofthe gel solution and to minimize bubbles (refer to figure 9 for guidance). Let it sit for 20 minutes to 1 hour to allow the gel to polymerize. During this time, ensure no leakage occurs. Use absorbent paper to clean any excess gel. Seal the top of the gel with additional solution (ensure the height is level with the flat glass), then insert the comb and let it sit for 30-45 minutes to allow complete polymerization.